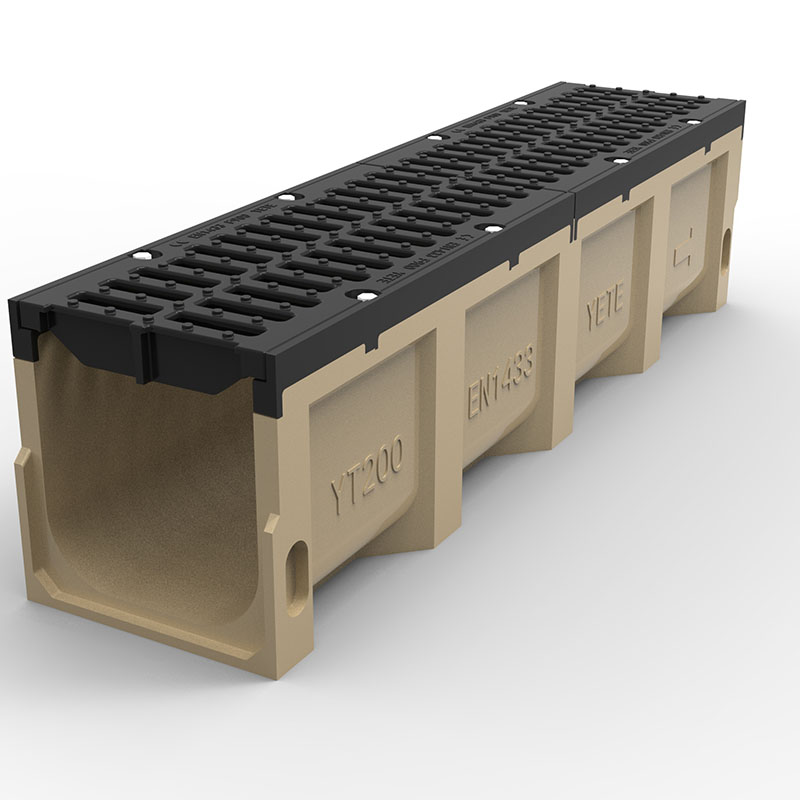

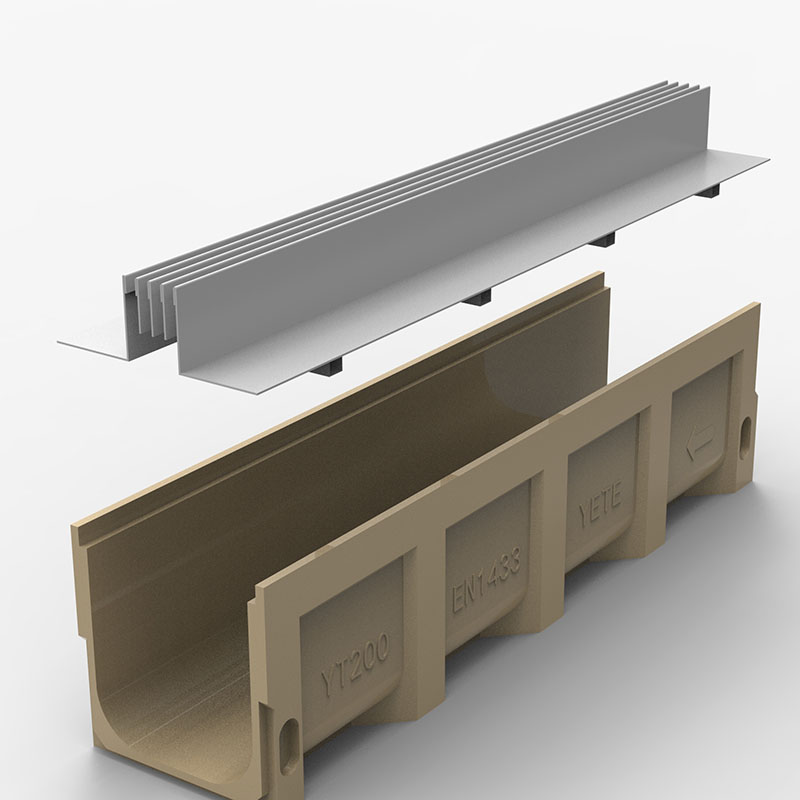

I-Monolithic Linear Drainage Channel

Incazelo Yomkhiqizo

Isiteshi se-monolithic drainage siwuhlelo lokudonsa amanzi lapho kokubili umzila kanye nesembozo kwenziwa ngesiqephu esisodwa. Isiteshi se-monolithic drainage senziwa iyunifomu kukhonkolo we-polymer. Le nto eluhlaza imele umthamo omkhulu kakhulu womthwalo kanye nekhono lokulondolozwa kwempilo ende. Kulokhu kwenezelwa isisindo esiphansi, lapho i-monolithic drainage channel ingafakwa kalula futhi kalula.

Izici Zomkhiqizo

Isiteshi se-monolithic drainage sinezici ezimbalwa ezihlukile:

1. Ukwakhiwa Okungenazihibe:Umzila wokudonsa amanzi we-monolithic uklanywe futhi wakhiwe njengeyunithi eyodwa, eqhubekayo, ngaphandle kwamalungu noma imithungo. Lokhu kwakhiwa okungenamthungo kuqinisekisa ukugeleza kwamanzi okushelelayo nokungaphazanyiswa, kunciphisa ubungozi bokuvala noma ukuvinjwa.

2. Amandla Aphezulu Nokuqina:Isiteshi se-monolithic sakhiwe kusetshenziswa izinto ezihlala isikhathi eside ezifana nokhonkolo oqinisiwe noma ukhonkolo we-polymer, okunikeza amandla amahle kakhulu nokuqina kwesikhathi eside. Iyakwazi ukumelana nemithwalo esindayo futhi imelane nokulimala kwezimoto, iyenze ifanelekele izindawo ezinabantu abaningi.

3. Idizayini eyenziwe ngokwezifiso:Isiteshi se-monolithic singenziwa ngendlela oyifisayo ukuze sihlangabezane nezidingo ezithile zephrojekthi. Ingaklanywa ngobubanzi obuhlukahlukene, ukujula, kanye nemithambeka ukuze isingathe ngempumelelo amazinga ahlukene okugeleza kwamanzi kanye nezidingo zokudonsa amanzi.

4. Ukugeleza Kwamanzi Okuphumelelayo: Ukwakhiwa okungenamthungo kwesiteshi se-monolithic kukhuthaza ukugeleza kwamanzi okusebenzayo, ukuqinisekisa ukugeleza kwamanzi ngokushesha nangempumelelo. Isiza ukuvimbela ukunqwabelana kwamanzi, inciphisa ingozi yezikhukhula, futhi igcine ubuqotho bezakhiwo ezizungezile.

5. Ukumelana Namakhemikhali Nokugqwala:Ngokuya ngezinto ezisetshenzisiwe, isiteshi se-monolithic singanikeza ukumelana okuhle kakhulu kumakhemikhali, kuhlanganise nama-acids nama-alkali. Lokhu kumelana kuyenza ifaneleke ukusetshenziswa ezindaweni zezimboni noma ezindaweni ezinokuchayeka okungaba khona ezintweni ezonakalisayo.

6. Ukufaka Okulula Nokunakekela:Idizayini engenamthungo yesiteshi se-monolithic yenza ukufakwa kube lula, njengoba awekho amalunga noma ukuxhumana okufanele ukhathazeke ngakho. Iphinde yenze kube lula ukulungiswa, ngezindawo ezimbalwa ezijwayele ukunqwabelana udoti noma umonakalo ongaba khona.

7. Izinhlelo Ezihlukahlukene:Ishaneli ye-monolithic drainage ilungele ukusetshenziswa okubanzi, okubandakanya imigwaqo, izindawo zokupaka, izindawo zezimboni, izindawo zokuhweba, nezindawo zokuhlala. Ingakwazi ukuphatha kahle ukugeleza kwamanzi ezindaweni ezihlukahlukene.

8. Ukuphepha Okuthuthukisiwe:Ukwakhiwa okungenamthungo kunciphisa izingozi ezikhubekayo futhi kuthuthukisa ukuphepha kukonke. Ihlinzeka indawo ebushelelezi yabahamba ngezinyawo, abagibeli bamabhayisikili, nezimoto, inciphisa ubungozi bezingozi noma ukulimala.

9. Ubude besikhathi nokusebenza kwezindleko:Ukwakhiwa okuhlala isikhathi eside kwesiteshi se-monolithic kanye nokumelana nokuguga kunomthelela ekuphileni kwaso isikhathi eside, okuholela ekwehleni kwezindleko zokusilungisa nokushintshwa ngokuhamba kwesikhathi.

Kafushane, umzila wokudonsa amanzi we-monolithic unikeza isisombululo esingenamthungo, esiqinile, nesisebenzayo sokugeleza kwamanzi okuphumelelayo. Ukwakhiwa kwayo okungenamthungo, ukuqina okuphezulu, ukuklama okwenziwa ngokwezifiso, kanye nezinhlelo zokusebenza eziguquguqukayo kuyenza ibe inketho ekahle ezindaweni ezihlukahlukene, iqinisekisa ukuphathwa kahle kwamanzi kanye nokusebenza kwezindleko zesikhathi eside.

Izicelo Zomkhiqizo

I-monolithic polymer drainage channel yekhonkrithi isebenza ngezinhloso eziningi ngenxa yokuguquguquka kwayo. Nazi ezinye izinhlelo zokusebenza ezibalulekile:

1. Ingqalasizinda yomgwaqo:Lezi ziteshi ziyizingxenye ezibalulekile zezinhlelo zokudonsa amanzi emigwaqeni nakuthelawayeka, ezilawula kahle ukugeleza kwamanzi angaphezulu ukuze kuqinisekiswe izimo zokushayela eziphephile futhi kuvimbele ukulimala komgwaqo.

2. Amasistimu wokudonsa amanzi emadolobheni:Badlala indima ebalulekile ezindaweni zasemadolobheni ngokuqoqa nokuqondisa ngokuphumelelayo ukugeleza kwamanzi eziphepho, benciphisa ingozi yezikhukhula nokunqwabelana kwamanzi emigwaqweni, emigwaqweni, nasezindaweni zomphakathi.

3. Izindawo Zokuthengisa Nezokuthengisa:Iziteshi zokudonsa ukhonkolo ze-monolithic polymer zivame ukusetshenziswa ezindaweni zokuthenga, ezindaweni zezentengiselwano, nasezindaweni zokupaka ukuze kulawuleke ukugeleza kwamanzi, ukuqinisekisa ukufinyelela okuphephile kwabahamba ngezinyawo kanye nokuvikela izakhiwo emonakalweni wamanzi.

4. Izinsiza zezimboni:Iziteshi zokudonsa ukhonkolo ze-monolithic polymer zisetshenziswa kabanzi ezindaweni zezimboni ukukhipha kahle amanzi angcolile, ukulawula uketshezi, nokugcina indawo yokusebenza ihlanzekile nephephile.

5. Izindawo zokuhlala:Lezi ziteshi zithola izinhlelo zokusebenza ezindaweni zokuhlala, okuhlanganisa i-driveways, izingadi, namavulandi, ukulawula ngokuphumelelayo ukugeleza kwamanzi nokuvimbela ukugcwala kwamanzi noma ukulimala kwempahla.

6. Ukwakheka Kwezwe kanye Nezindawo Zangaphandle:Bavame ukuqashwa ezinhlelweni zokuhlelwa kwezindawo, amapaki, nezingadi ukulawula ukuphuma kwamanzi, ukuvimbela ukunqwabelana kwamanzi nokuqinisekisa impilo yezitshalo nokuzinza kwenhlabathi.

7. Izinsiza zezemidlalo:Lezi ziteshi zifakwa ezinkundleni zemidlalo, ezinkundleni zemidlalo, nasezindaweni zokungcebeleka ukuze zikhiphe amanzi emvula ngendlela efanele, zinikeze izimo zokudlala ezikahle futhi kuncishiswe ingozi yokulimala.

8. Izikhumulo zezindiza kanye Nezindawo Zokuthutha:Iziteshi zokudonsa ukhonkolo ze-monolithic polymer zibalulekile ekulawuleni ukugeleza kwamanzi emigwaqweni yezindiza zezindiza, emigwaqweni yamatekisi, nakwezinye izindawo zokuhamba, ukuqinisekisa ukusebenza okuphephile nokunciphisa izingozi.

9. Amakhishi Okucubungula Ukudla Nezimboni:Zifanele izindawo ezidinga ukuhlanzwa njalo, njengezindawo zokucubungula ukudla namakhishi ezimboni, ukukhipha uketshezi ngokuphumelelayo nokugcina izindinganiso zokuhlanzeka.

Kafushane, umzila wokudonsa amanzi kakhonkolo we-monolithic polymer uthola ukusetshenziswa okubanzi kwingqalasizinda yemigwaqo, izindawo zasemadolobheni, izindawo zentengiso, izindawo zokuhlala, izindawo zezimboni, amaphrojekthi okulungisa umhlaba, izikhungo zezemidlalo, izikhumulo zezindiza, nezindawo zokucubungula ukudla. Ukwakhiwa kwayo okungenazihibe, ukuqina kwayo okuphezulu, namandla okuphatha amanzi ngendlela efanele kuyenza ibe yingxenye ebalulekile yokuqinisekisa ukuphepha, ukusebenza, kanye nokuphuma kwamanzi okusebenzayo ezindaweni ezihlukahlukene.

Layisha Ikilasi

A15:Izindawo ezingasetshenziswa kuphela abahamba ngezinyawo nabahamba ngamabhayisikili

B125:Izinyawo, izindawo zabahamba ngezinyawo, izindawo ezifanayo, izindawo zokupaka izimoto ezizimele noma izindawo zokupaka izimoto

I-C250:Izinhlangothi zokunqanda nezindawo ezingashushumbiswa kuzo zamahlombe esandla nokunye okufanayo

I-D400:Imigwaqo yemigwaqo (okubandakanya imigwaqo yabantu abahamba ngezinyawo), amahlombe aqinile nezindawo zokupaka, yazo zonke izinhlobo zezimoto zomgwaqo

I-E600:Izindawo ezithwele kanzima ngamasondo, isb. amachweba nezinhlangothi zedokhi, njengamaloli e-forklift

F900:Izindawo ezibhekene nomthwalo ophakeme kakhulu wamasondo isb

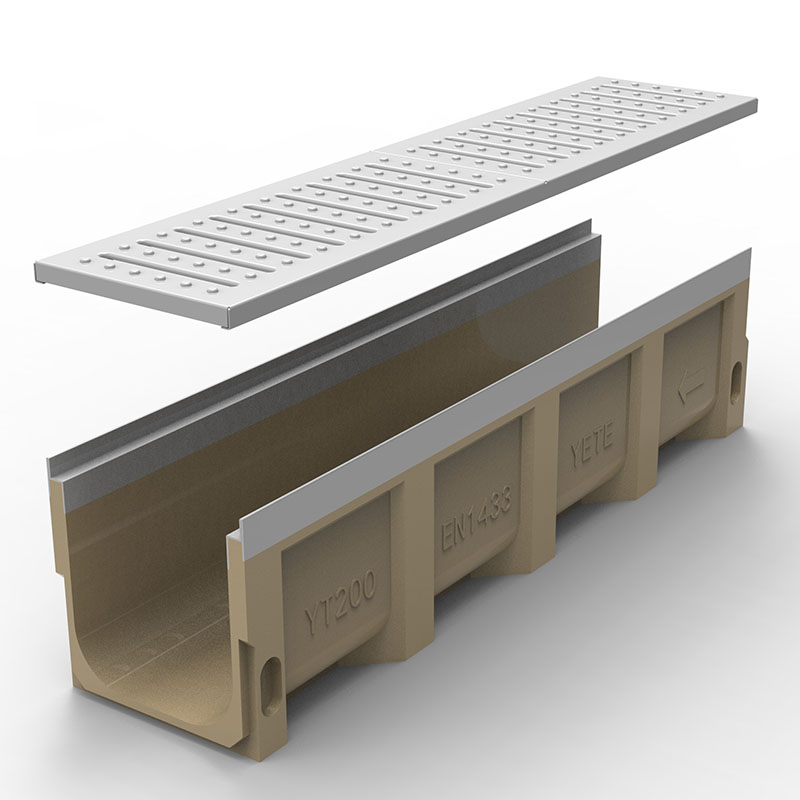

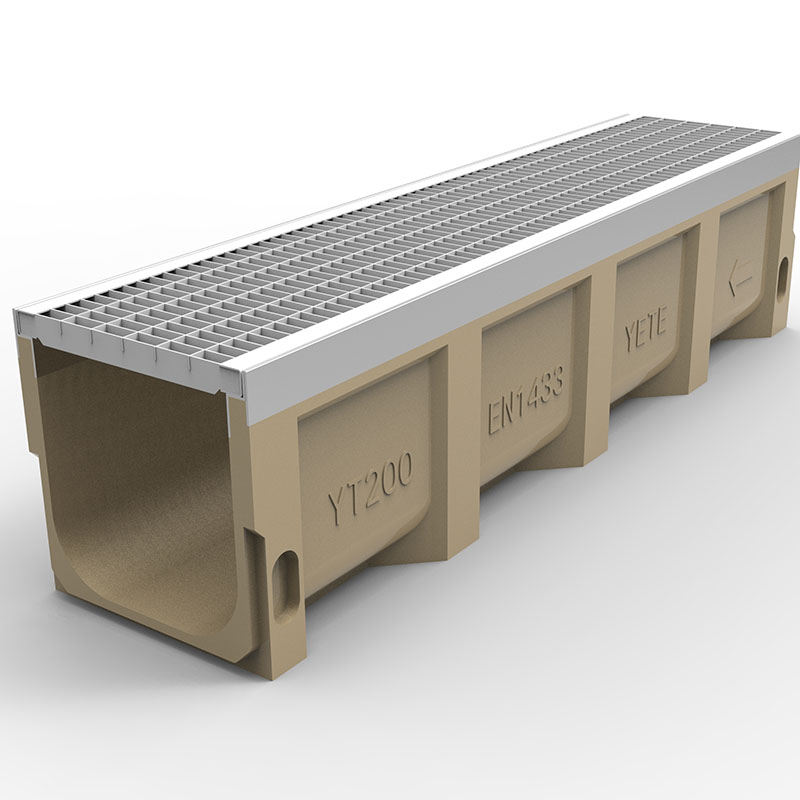

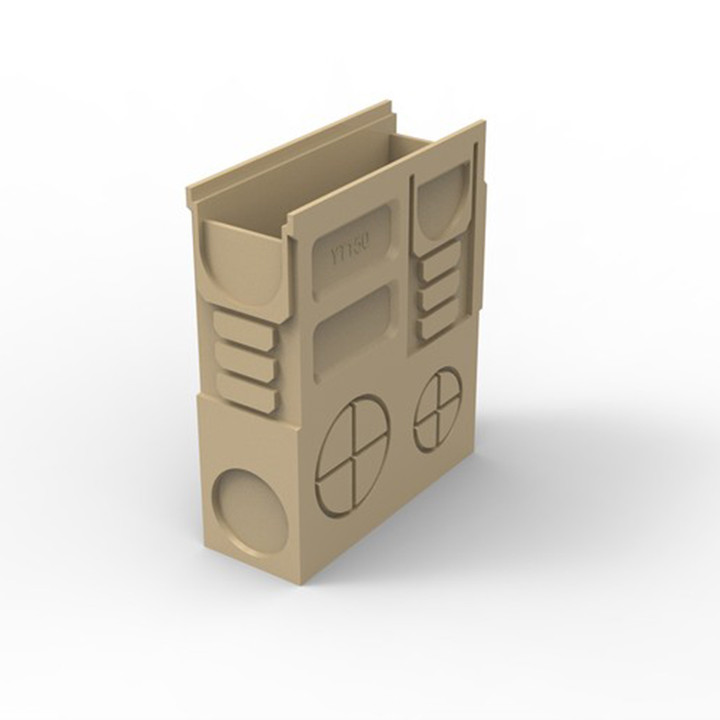

Izinketho Ezihlukene

Izitifiketi

Ihhovisi kanye Factory